Our Competences

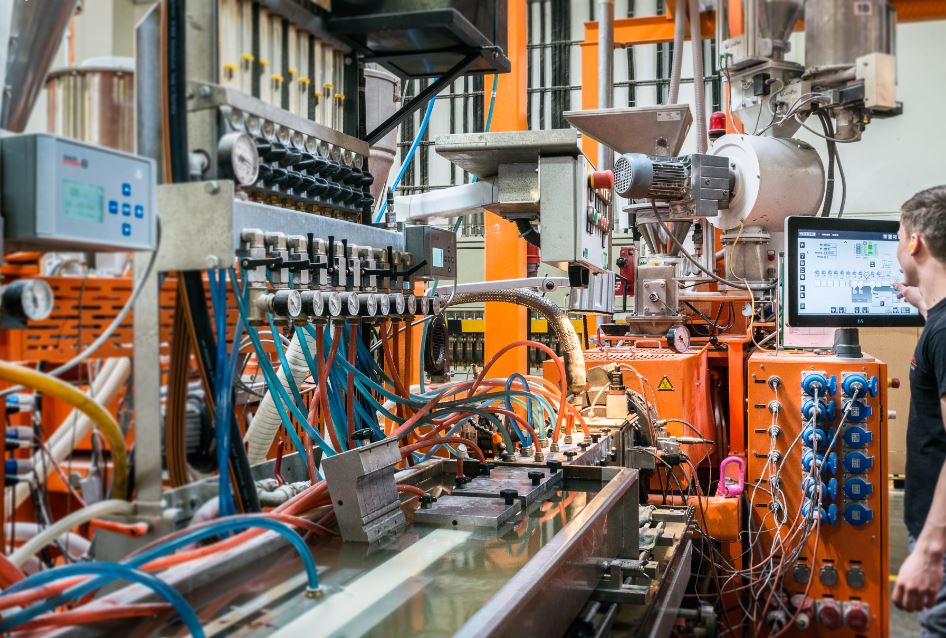

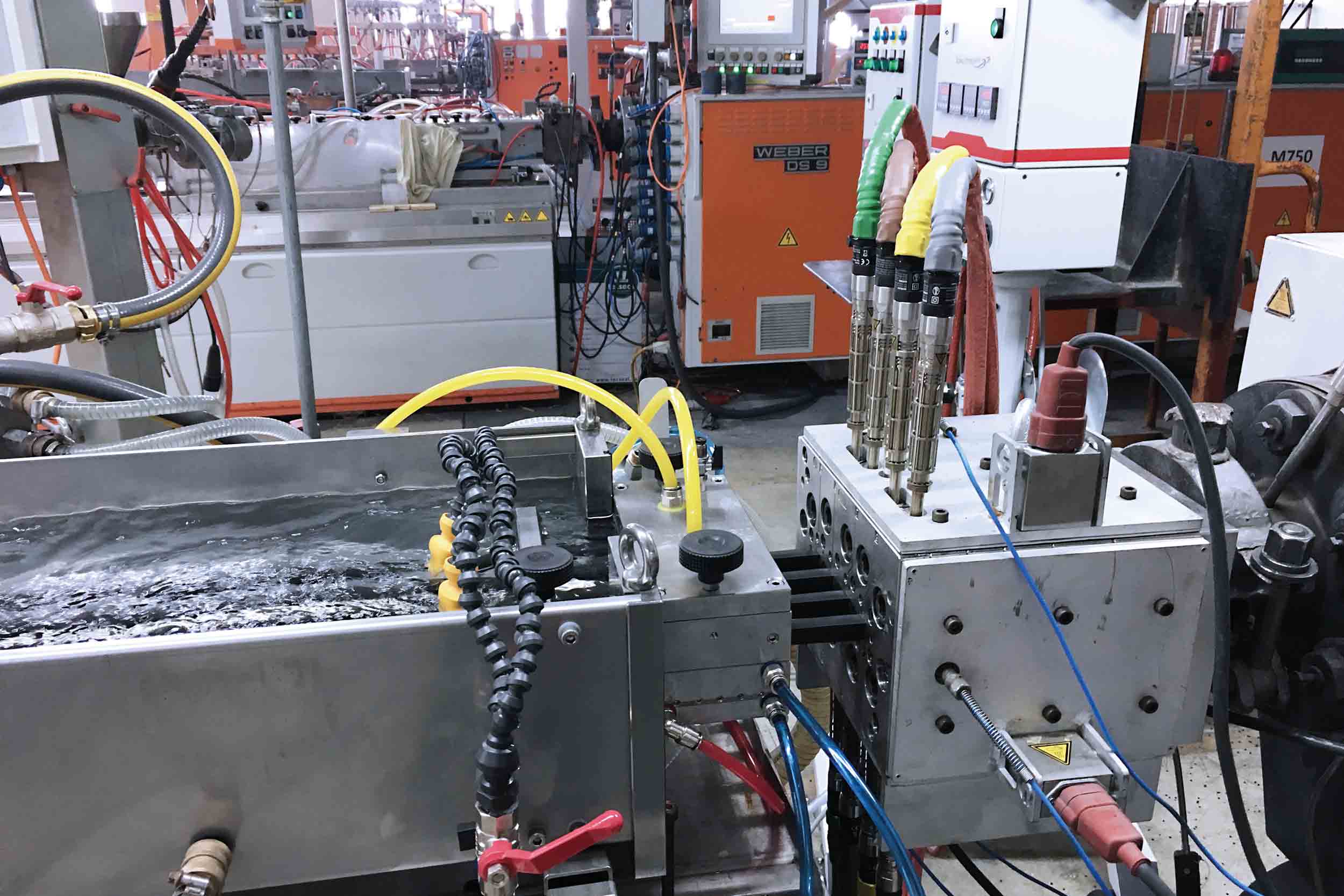

100 extrusion lines at 5 production locations with hourly outputs between 50 and 300 kg ensure maximum project reliability.

Logistics

We are in a future-oriented company with a modern-day organisation and flat hierarchy. Because of our continuous expansion, we are permanently on the lookout for qualified specialists and managers, as well as committed trainees – on a worldwide basis.

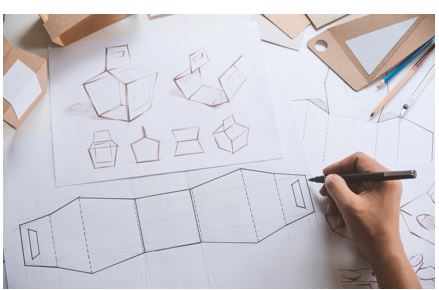

Design

Our designers will support on all aspects of the design, development and implementation of your projects.

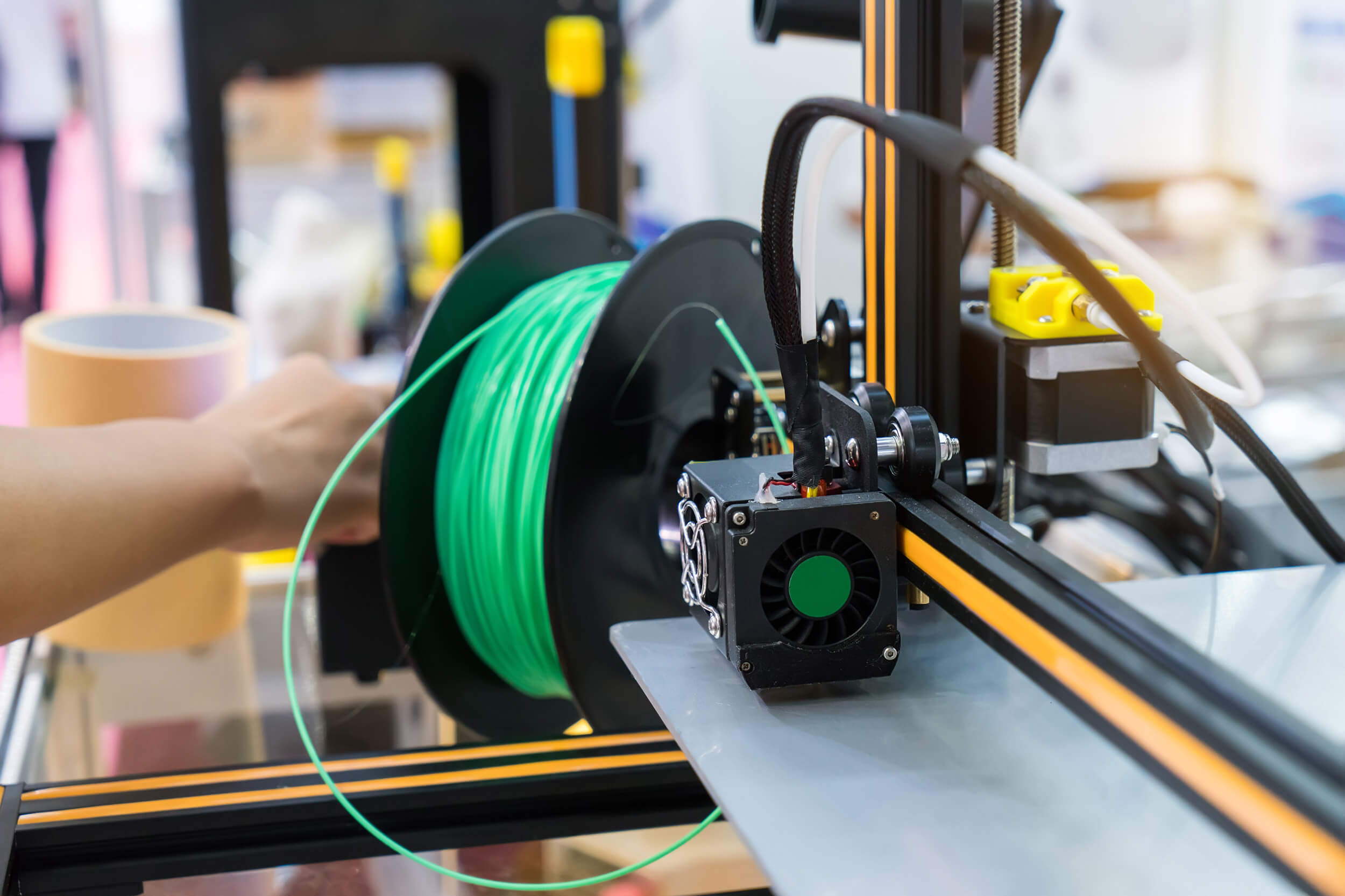

3D printing method

We are masters of 3D printing processes.

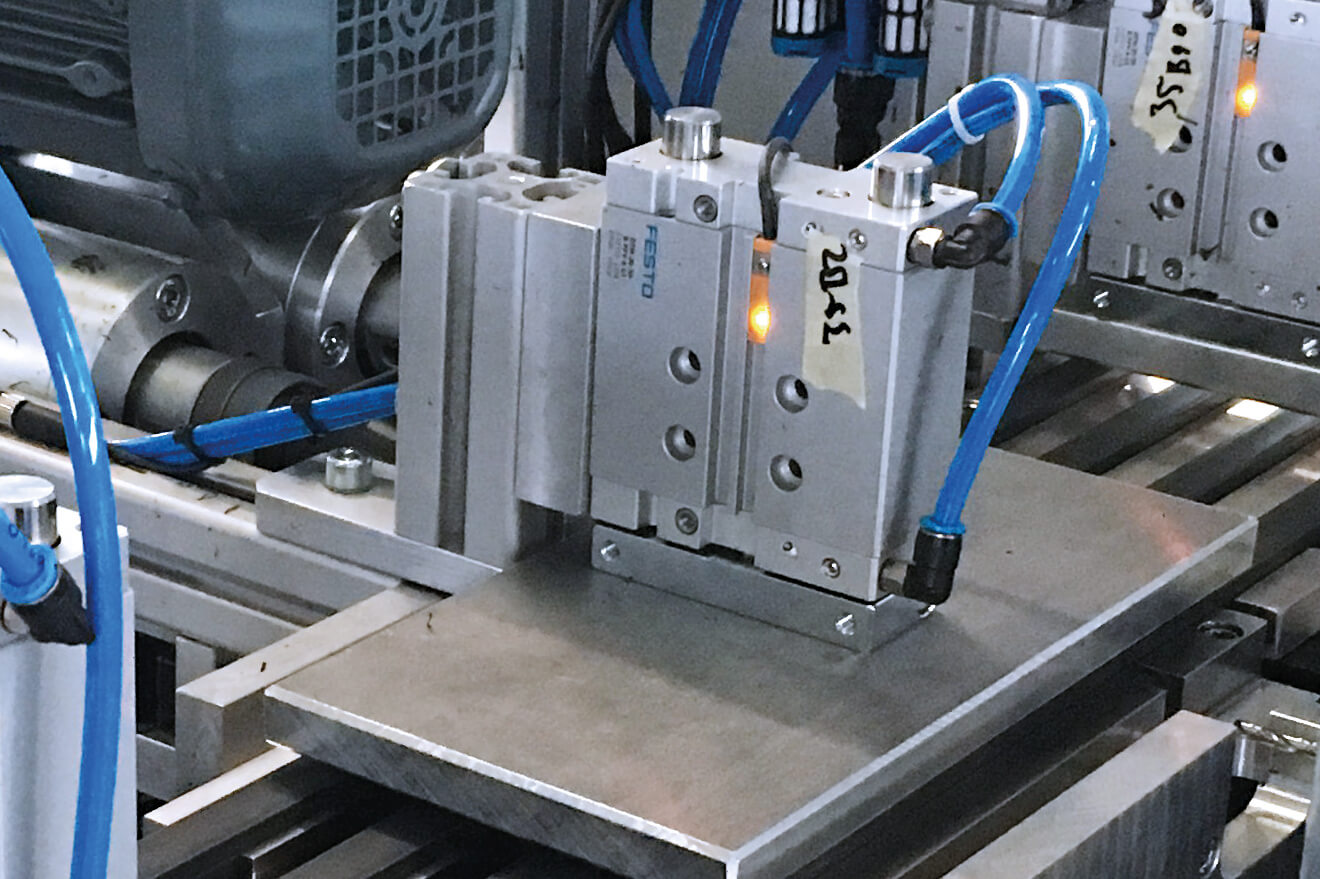

Tool Construction/Tool Maintenance

We operate our own in-house machine tooling capability, which guarantee’ the design of new tools as well as a permanent tool maintenance programme.

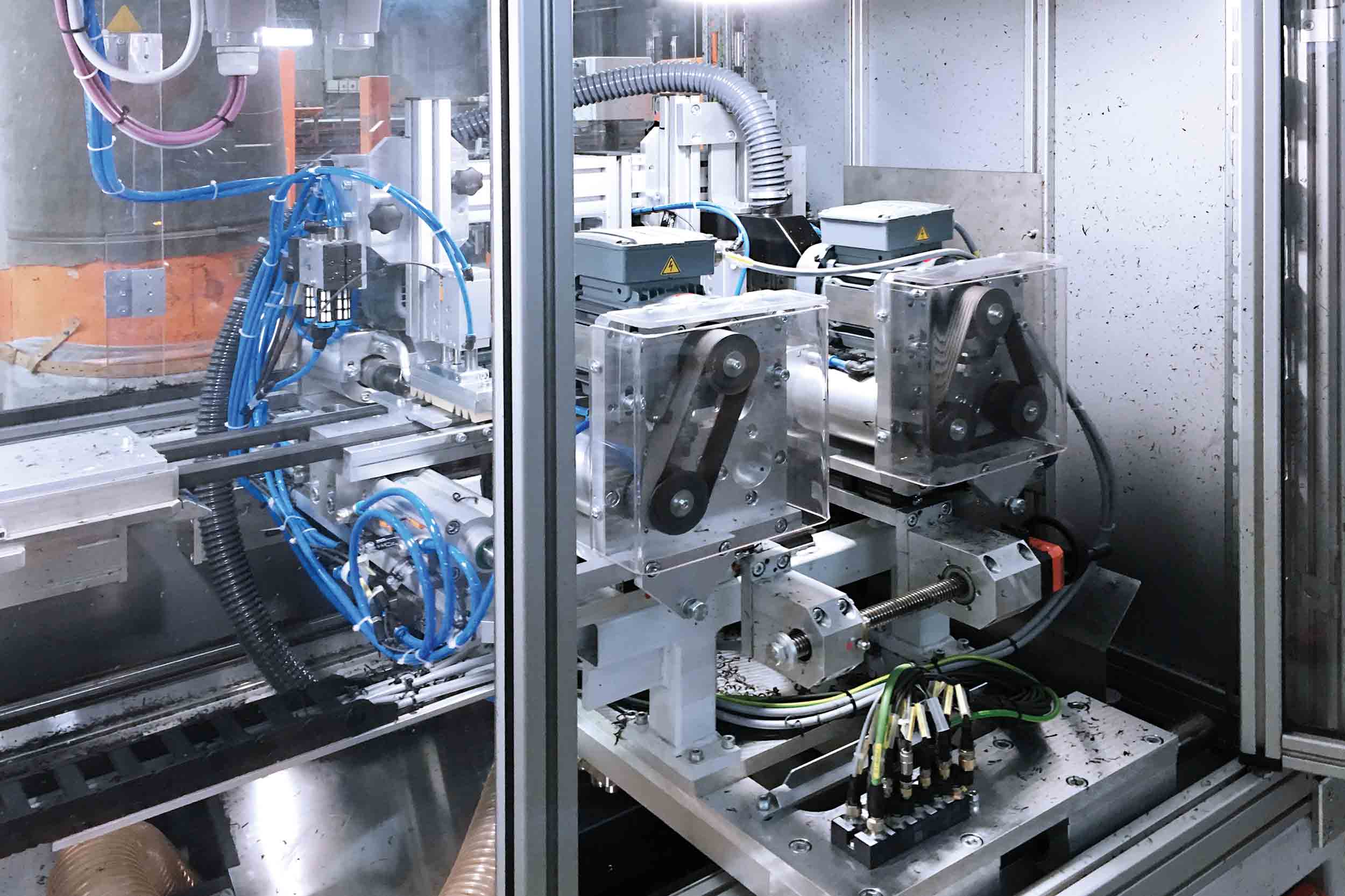

Industrial engineering/Unit construction

Döllken Profiles employs the latest equipment in production.

Material development

You set the specification, we’ll do the rest. From material development through to the finished product.

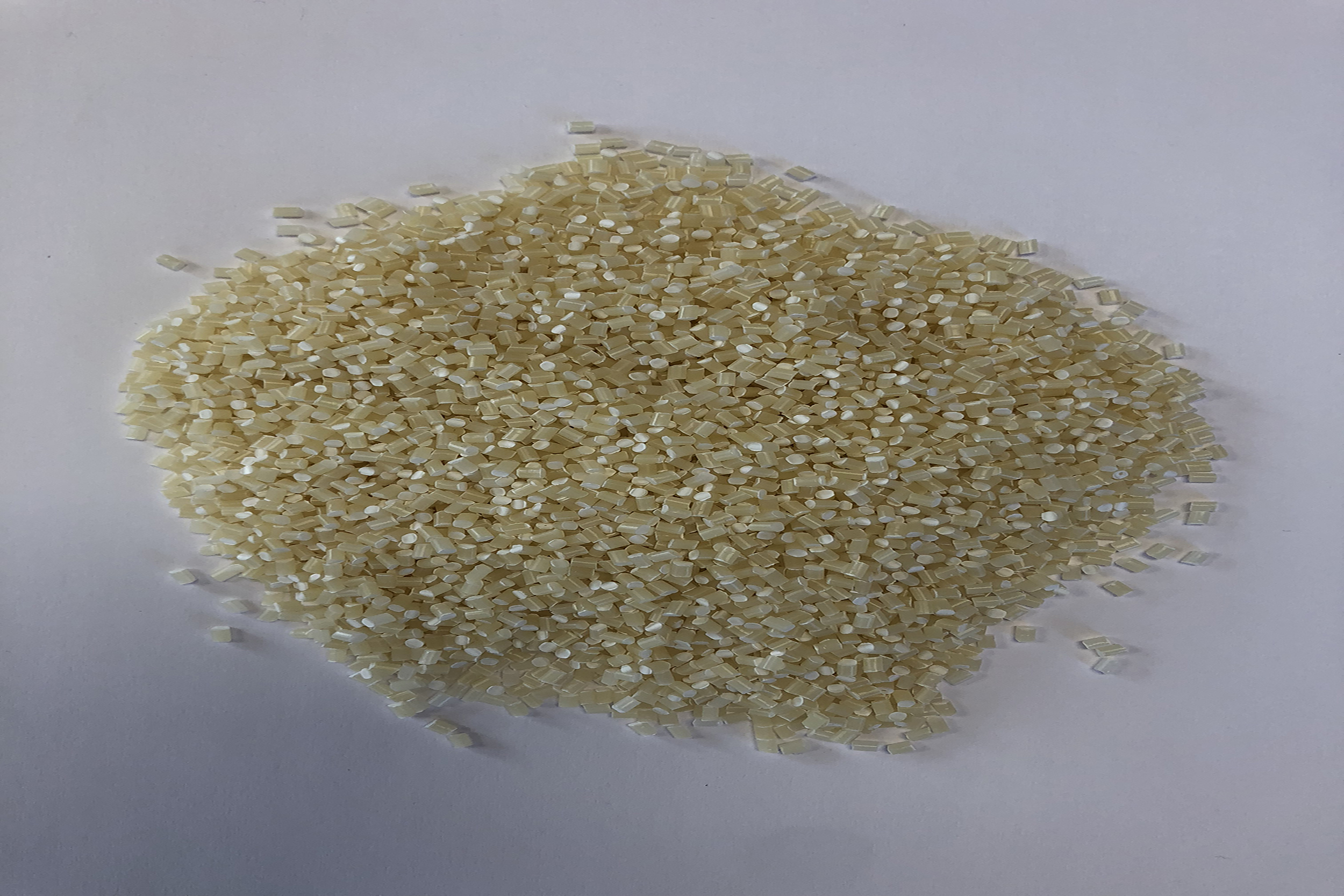

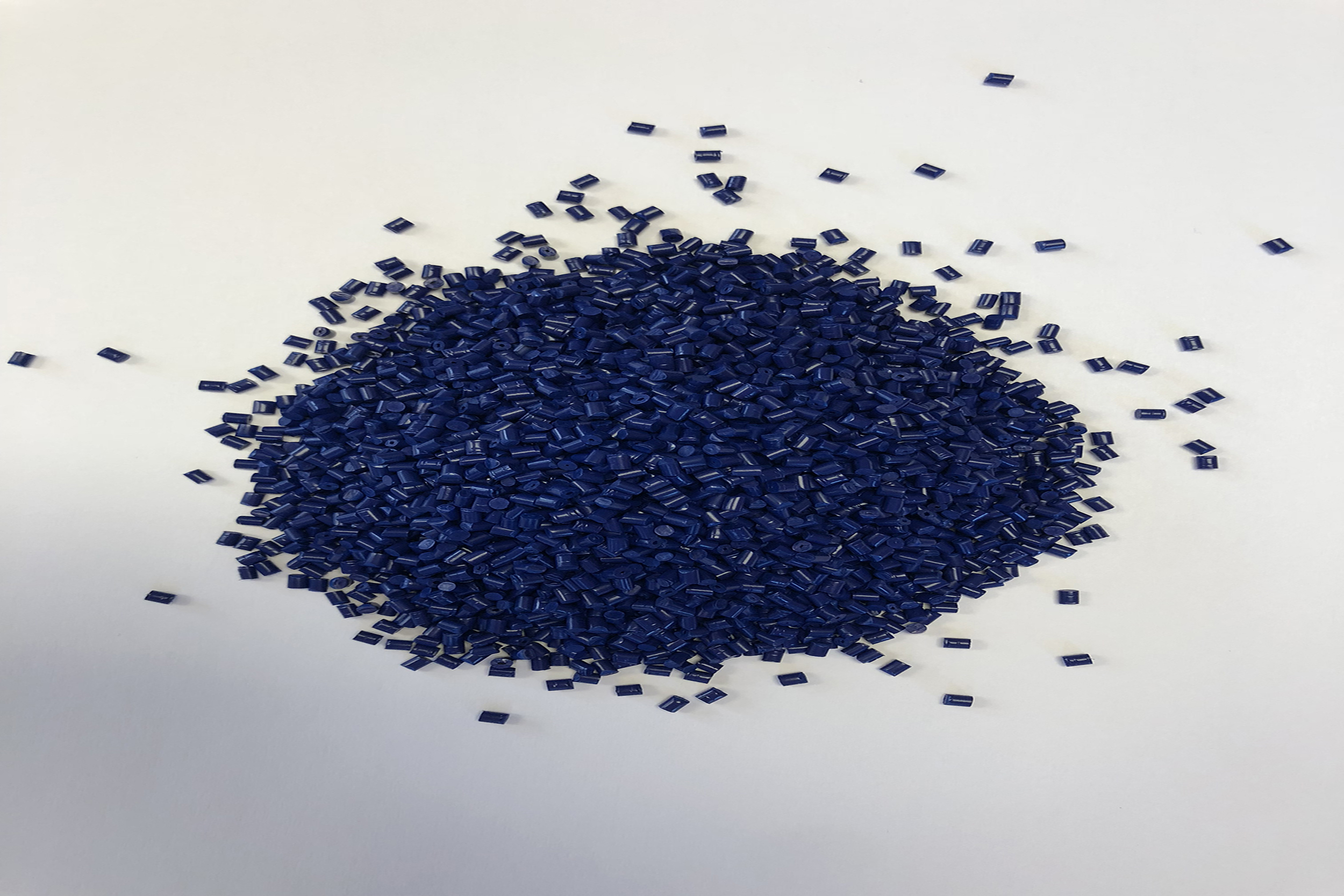

Mixing/Colour mixing/Compounding

Regardless of the colour of your product, we have the technology to produce it for you.

Recycling

We aim to achieve our goal of zero-waste production. Our highest priority is therefore the careful use of resources.

Ready-made division

Our roller shutter systems are only one of the many products that we prepare for shipment in our packaging department.

Specialist surface technologies

We are surface technology masters – feel free to get in touch.

Project Management

We work using the latest project management methods in order to successfully reach your objective.

DIN EN ISO 9001:2015 Quality Management System

The certification of our existing quality management system in accordance with ISO 9001 provides us with a transparent and unbiased assessment of our services all over the world. The ISO 9001 standard is regarded as a quality benchmark worldwide.

DIN EN ISO 14001:2015 Environmental Management System

We see it as our duty to protect the environment, and environmental pollution generated as part of our business is avoided as far as possible, and/or minimised on an ongoing basis, and we are very aware of our impact, also on the quality-of-life of future generations. This also applies to the development and planning of new products and processes.

DIN EN ISO 50001:2016 Energy Management System

When creating our products and designing processes, we strive to continuously improve our specific energy consumption (i.e., increase our energy efficiency).

Green Guard Gold Certification

Our products have been awarded the Greenguard Gold certificate.

Training

We are in a future-oriented company with a modern-day organisation and flat hierarchy. Because of our continuous expansion, we are permanently on the lookout for qualified specialists and managers, as well as committed trainees – on a worldwide basis.

Polyvinylchloride hard (PVC-U)

PVC-U has very good chemical and light and weather resistances. The use of appropriate additives allows its properties to be adjusted from hard and brittle through to (highly) impact-resistant. The use of propellants allows the production of foamed profiles.

Polyvinylchloride soft (PVC-P)

The use of plasticisers modifies the inherently hard PVC substance into a soft, elastic material. All this, without impacting its excellent light and ageing resistance characteristics.

Acrylonitrile Butadiene Styrene (ABS)

ABS is a terpolymer of three monomers – acrylonitrile, butadiene and styrene. ABS have excellent rigidity and impact resistance properties. Because of its low resistance to ultraviolet light, it is not suitable for outdoor use.

Polystyrene (PS)

Homopolymers made from monostyrene are hard, brittle substances, and they are therefore prone to break under impact stress. Rubber-modified polystyrene has a significantly improved property profile in terms of impact resistance.

Polypropylene (PP)

Polypropylene is a member of the polyolefin group and is a highly versatile plastic with greater resistance to chemicals, impact and improved heat resistance than polyethylene.

Polycarbonate (PC)

Polycarbonate is an extremely impact resistant plastic, which also combines high rigidity and a wide range of thermal applications, and very good visual characteristics and is widely used in lighting applications.

Polyamide (PA)

Technically significant polyamides are characterised by their high strength, rigidity and toughness, as well as their good chemical resistance characteristics.

Acrylonitrile Styrene Acrylate copolymers (ASA)

When a polymer is styrene-acrylonitrile based, it has similar characteristics to Acrylonitrile butadiene styrene, as well as very good ageing- and weather-resistance characteristics.

Polymethyl Methacrylate (PMMA)

PMMA is a crystal-clear material with a high surface gloss and brilliance. It has excellent tensile, pressure and flexural strength, and is largely scratch-resistant.

Polymer blends (PC/ABS)

ABS and PC-based polymer blends combine the good mechanical characteristics of the individual materials and have high impact and heat resistance.

Thermoplastic Elastomers (TPE)

The term TPE refers to materials which combine the characteristics of rubber with those of thermoplastics. TPE is as soft as rubber but can be plastically deformed by heat. There is a variety of thermoplastic elastomers which differ in terms of their chemical structure, and which therefore offer different advantages in terms of cost, resistance and mechanical properties.

Polyethylene (PE)

Polyethylene is one of the most widely used plastics and is a member of the polyolefin group. It is characterised by its low density, toughness and high resistance to chemicals, but it also has low hardness and temperature resistance characteristics.

Thermoplastic Polyurethane (TPU)

TPUs are produced by polymerising diols and polyisocyanates. Depending on their initial monomers, they are characterised by their high wear, abrasion and tensile strengths, as well as by their high tear resistance; they are also UV-stable and resistant to chemicals.

Polyethylene Terephthalate (PET)

PET is characterised by its excellent dimensional stability, creep strength and good sliding and wear resistance performance.

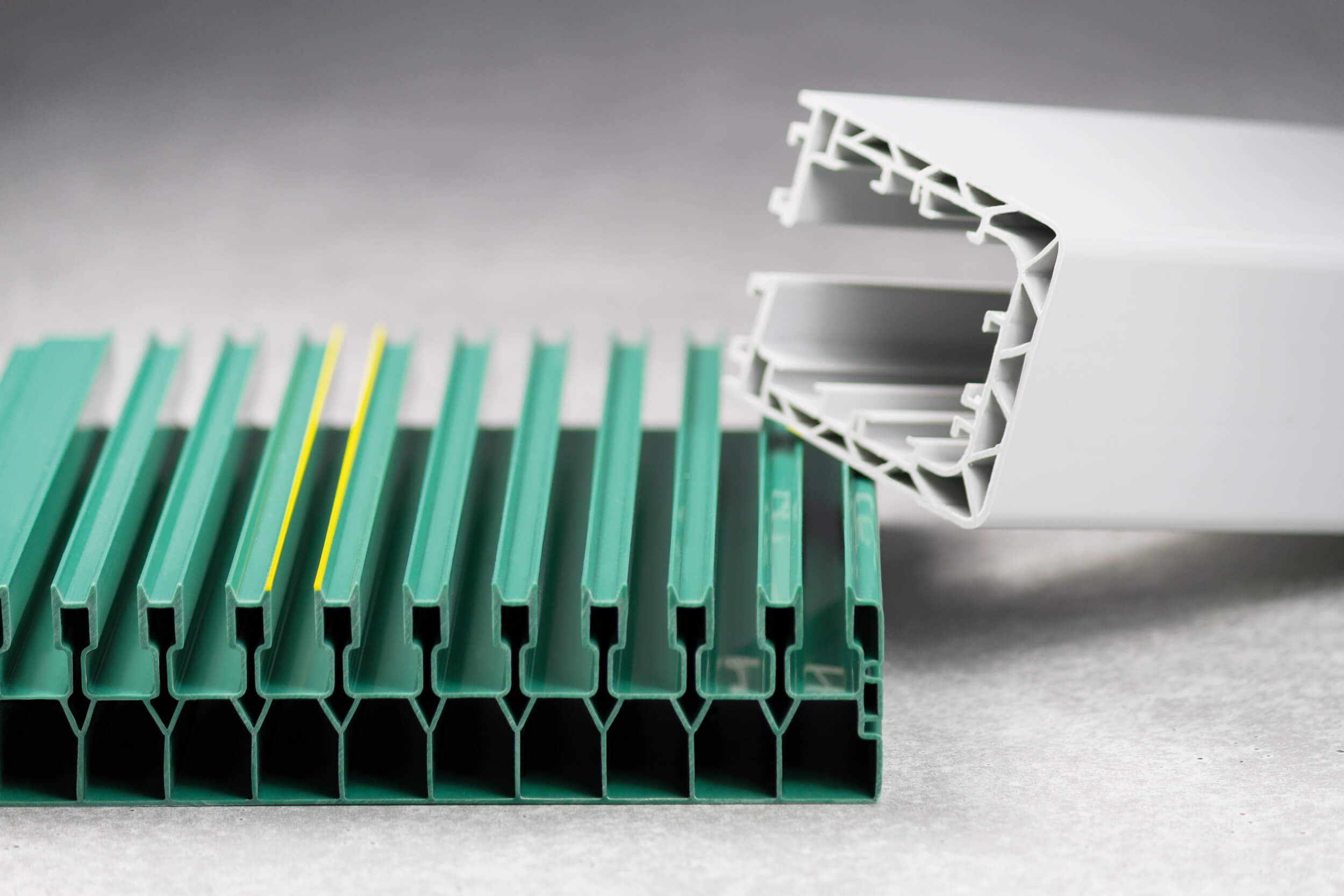

Co-Extrusion/Tri-Extrusion

Multiple extrusion refers to the feeding of two or three materials through the same extrusion tool. The respective materials can be combined through the use of various extruders. This enables the production of multicoloured profiles.

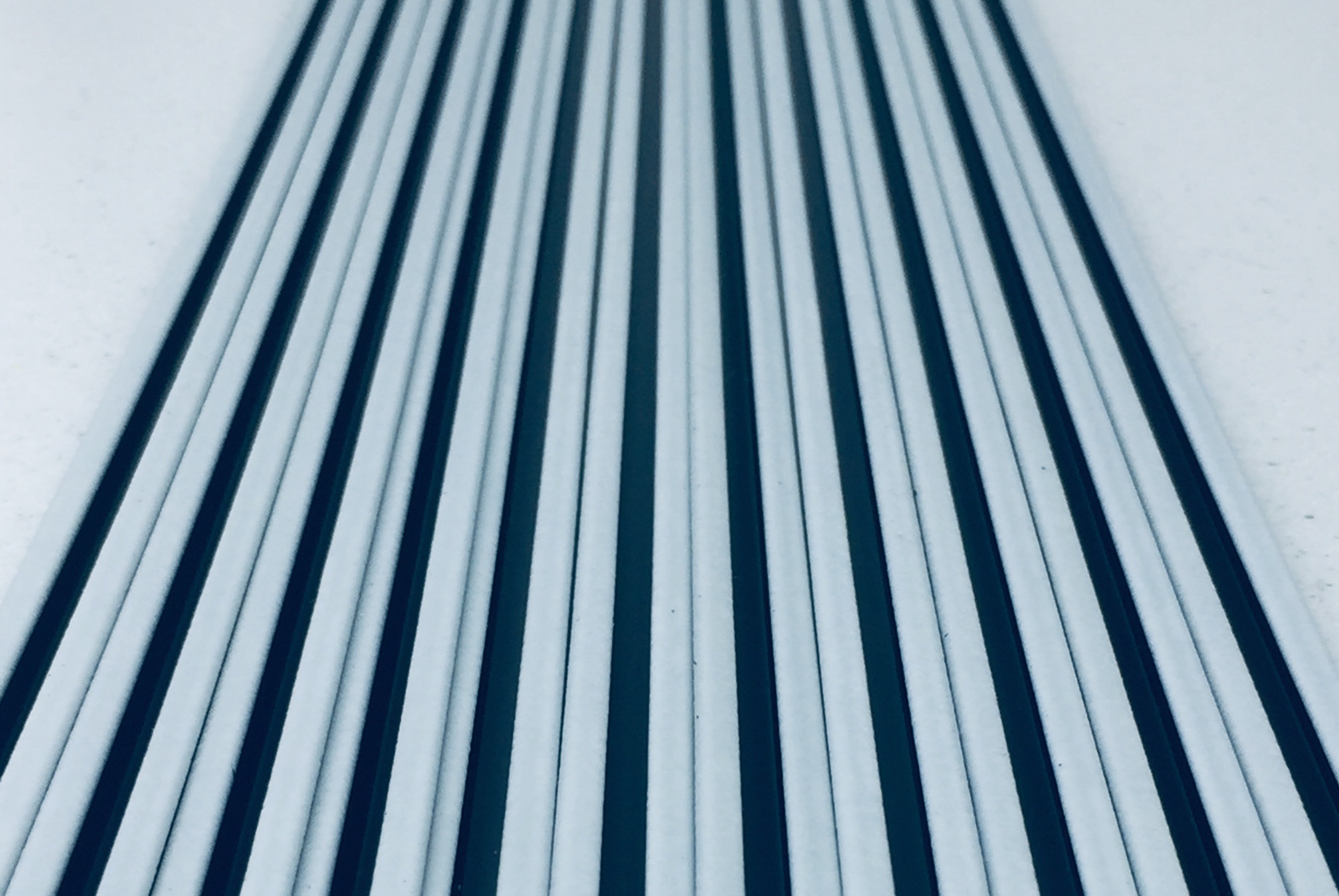

Multi-strand (up to 4-fold with flow control)

Here, the desired profile is manufactured using the multiple extrusion principle. Up to 4 identical profiles can be manufactured on a single extruder at the same time.

LED (multiple co-extrusion)

LED co-extrusion then coats the conductor films completely with thermoplastic material using a patented process. This material is free from chlorine and halogens and thus creates a healthy and above all long-lasting protection against mechanical influences, water, salt, oil, fuels and chemicals.

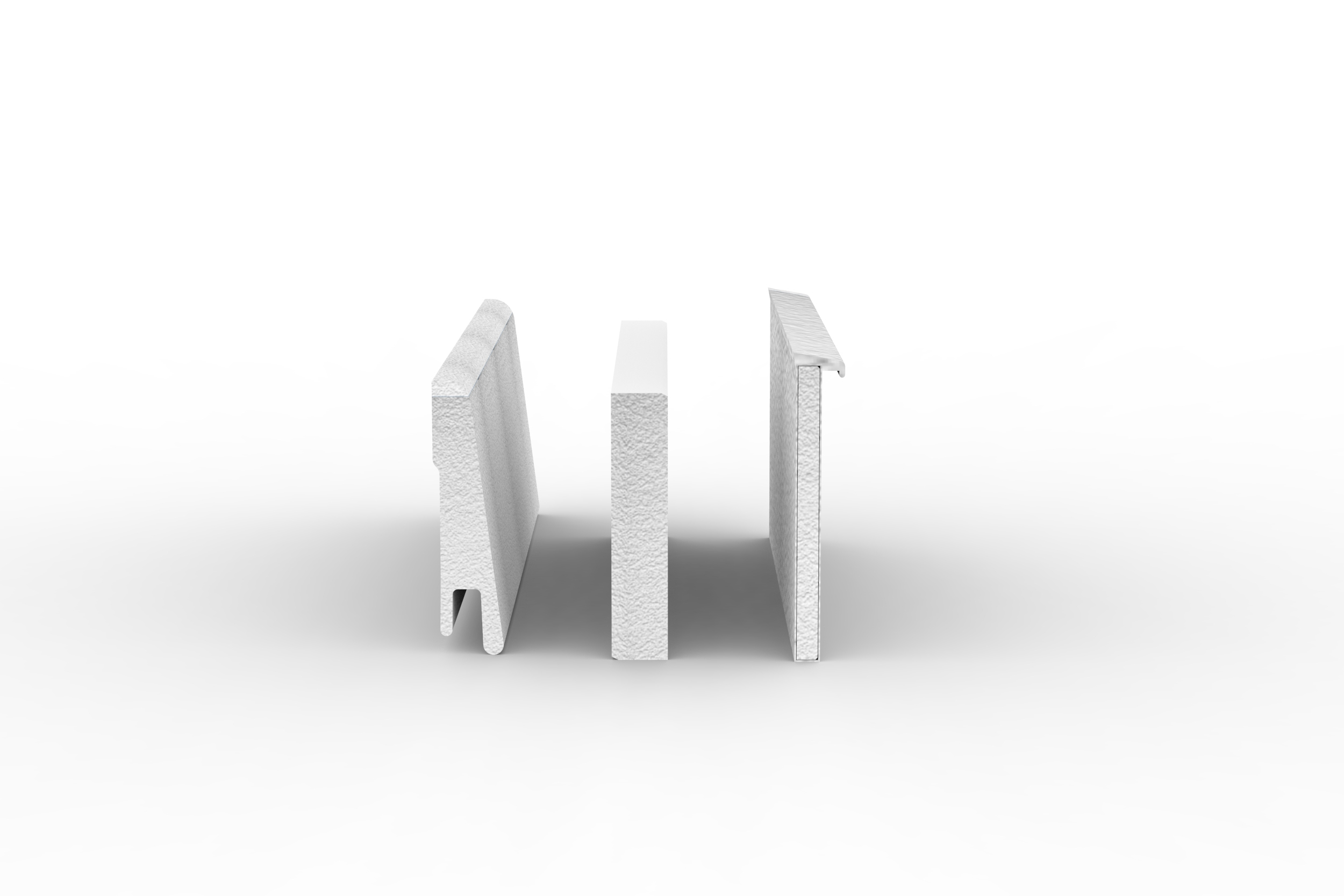

Foam extrusion (H-PVC)

Foam extrusion refers to a plastic whose structure is made up of multiple cells (cavities and pores enclosed in the base material). Almost all plastics can be used in foams.

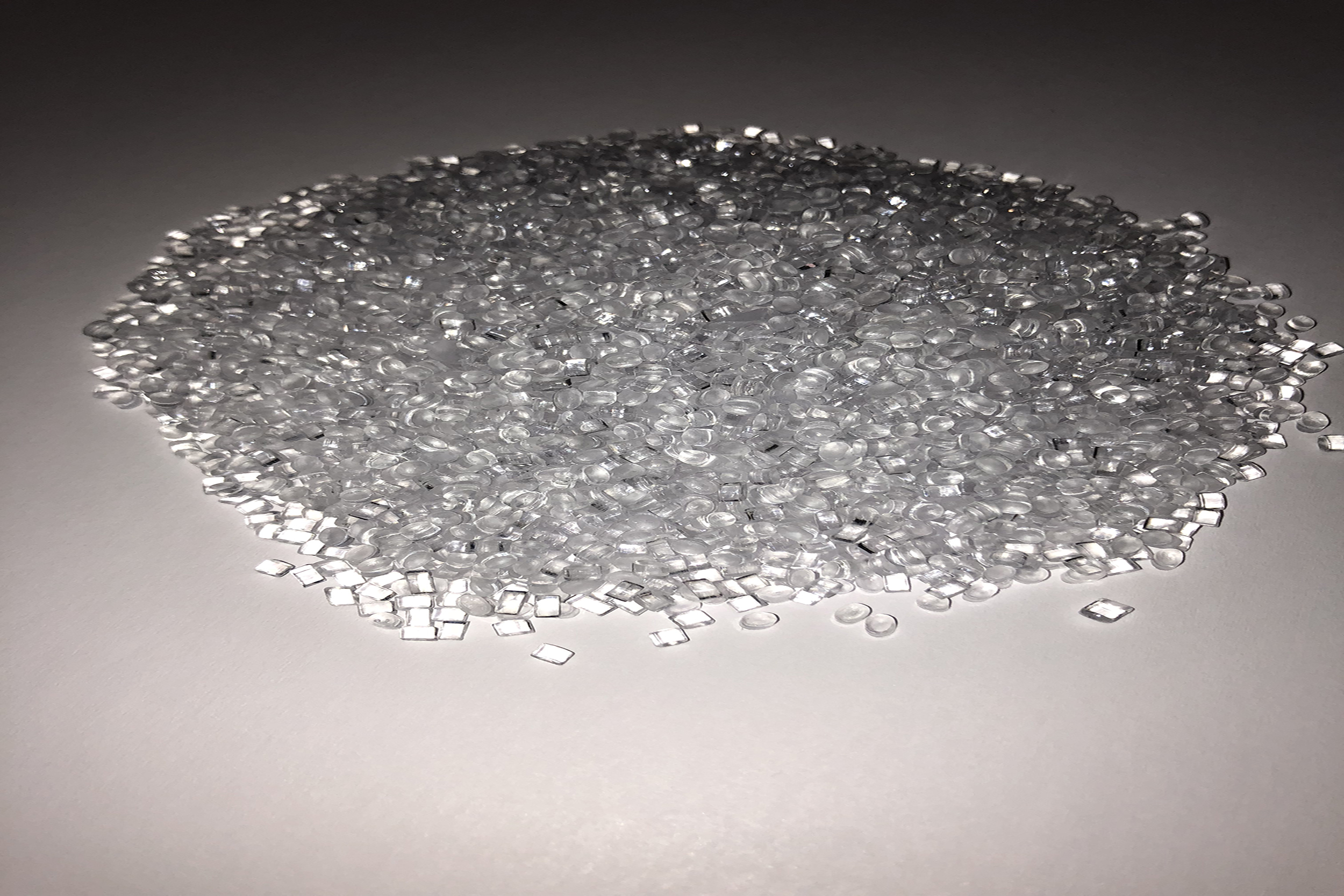

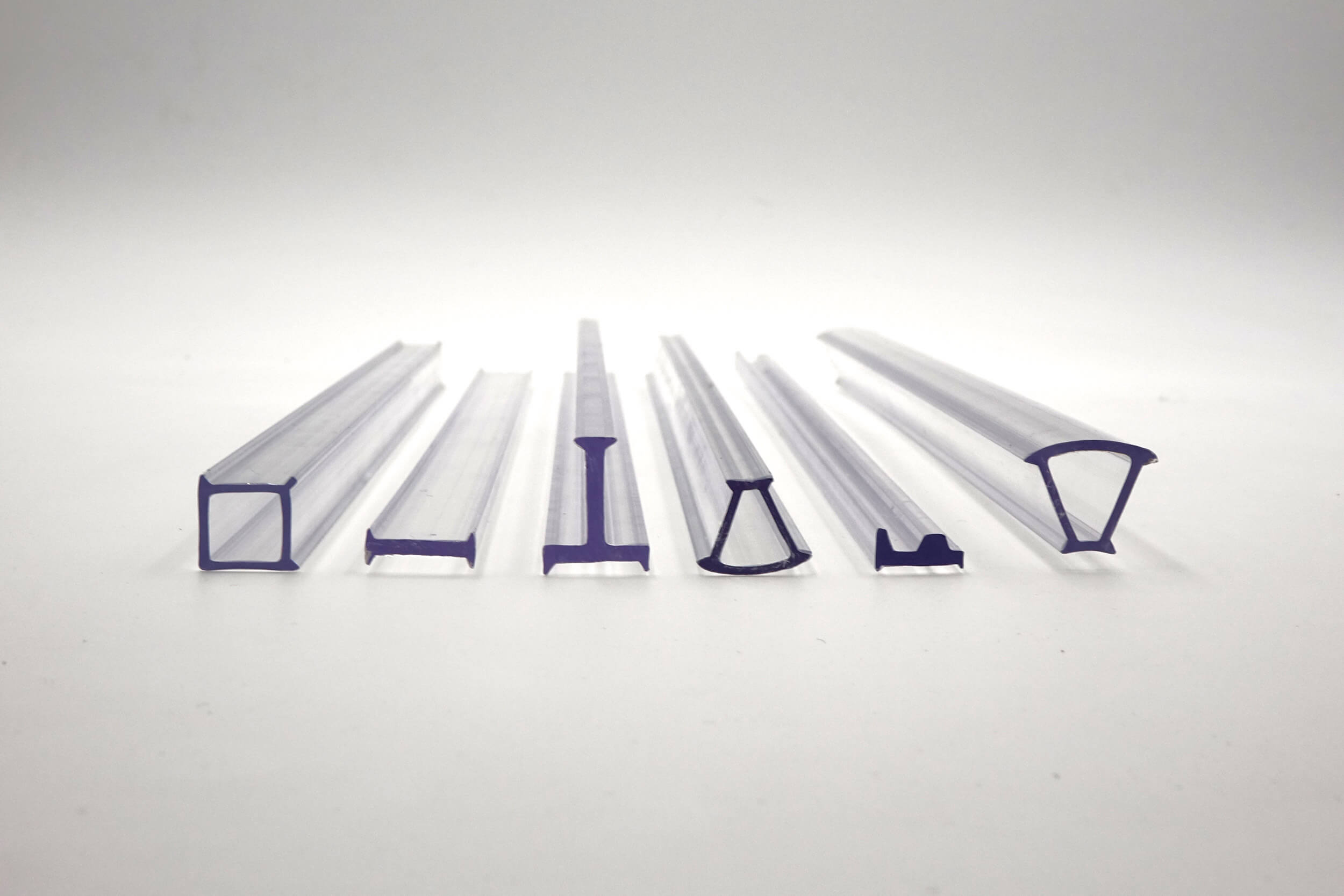

Crystal clear profiles

Acrylic profiles are characterised by their high light transmission. In addition, they are also UV-stable, and can be found in illuminated advertising, lighting or display areas.

Special sliding layers

Special (cost-efficient) overlay formulations in profile sections are already in use in a wide range of industry sectors. In sensitive production areas (e.g. painting lines), they are also teflon-free.

Hollow chamber profiles

Highly demanding hollow chamber profiles in combination with the narrowest window tolerances. We guarantee you the professional execution of your initial idea right through to the launch of your product.

Inline foiling and wrapping

Perfect visual synergies, decorative foils or wrapping can be achieved in-line and individually adaptable to your specifications.

Inline punching, drilling, milling

Effective assembly of your profiles right on the production line. Drilling, punching or milling profile end processing.

Aluminium/copper/steel strip inlays

There are many challenges to overcome. Matching the linear expansion of different construction components or materials, magnetic applications or electrification, all can be embedded into the profile shape that you want.

Volumetric/graphimetric dosage

Gravimetric dosage is controlled according to weight. The weighing process lengthens cycle times. In most cases, the container with the material to be dosed is positioned on a scale, and the weight reduction after application corresponds to the dosage amount. Volumetric dosage refers to a constant output volume. Flow sensors enable the precise measurement of a mass or volume which passes through a tube.

Colouring with liquid colours

In this case, the specific colour of the granules is adjusted using liquid colours.

Fixed lengths +/- 0.5 in line

The profiles are punched or cut to the desired length as production proceeds on the production line.

Coiling techniques

Equipped either with a horizontal or vertical coiling axis or a drum coiler, these enable tension-free, sensor-controlled coiling of a wide variety of profiles.

Automated packaging

Increased profitability thanks to intelligent, integrated and automated packaging processes.

Offline production

Product processing on the production line is not always technically feasible or economically viable. In such cases, you can take advantage of our internal assembly team. Get in touch if you are looking for ready-to-install solutions.